From Legacy Systems to Smart Logistics Platforms: Why Modernization Became a Competitive Advantage in 2025

For years, logistics companies ran operations on legacy ERP and TMS systems designed for stability, not agility. These monolithic solutions lacked integration, offered limited visibility, and could not scale with new models of delivery such as next-day fulfillment, gig workforce, micro-warehousing, and real-time dispatching. By 2025, the term modernization will have lost its digital transformation buzzword character and will have become a main factor in unit economics, SLA compliance, and customer satisfaction directly.

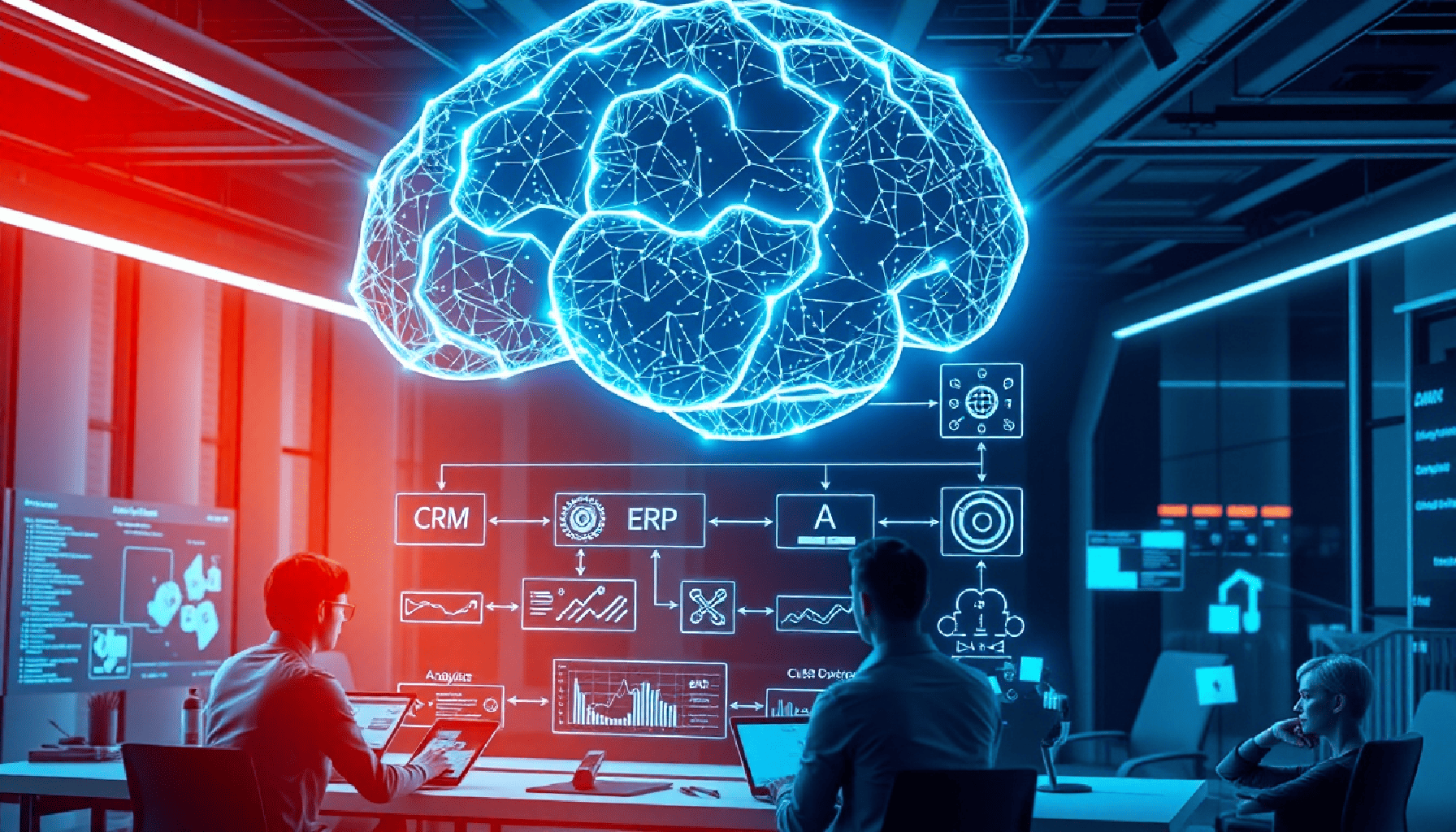

The digital supply chains of today require highly advanced platforms that perform such functions as processing operational data in real-time, integrating IoT, and routing through AI models, and at the same time allowing data-driven decision-making. This change is structural, not superficial: firms are not just upgrading the systems that manage logistics but rather buying platforms that enhance logistics.

What’s Wrong with Legacy Logistics Infrastructure

Most legacy logistics systems were built for predictable supply chains. Modern logistics is volatile, fragmented, and faster than ever. Key constraints include:

- Manual reporting and delayed visibility

- Limited API integrations with carriers and 3PLs

- No predictive analytics or forecasting

- High cost of customization

- Incompatibility with IoT hardware and telematics

- Security and compliance gaps

- Vendor lock-in and slow rollout cycles

The old ERP and TMS systems used for transport and logistics were never designed to cope with the last-mile delivery changes, e-commerce expansion, fleet management, and sustainability assessment that customers and regulators demand. According to the analysts' forecast, by 2026, more than 70% of logistics modernization projects would have either AI or advanced analytics technology incorporations (Gartner).

From Systems of Record to Systems of Intelligence

Modern platforms introduce a new paradigm: operations shift from transactional systems of record to predictive systems of intelligence. This evolution changes supply chain fundamentals:

The main factors responsible for the modernization of logistics and supply chains are listed below:

- IoT telematics, connected fleets, and asset tracking technology have made it possible to have real-time visibility over all the processes concerning various stages of the supply chain and logistics.

- Demand forecasting, delay prediction, and dynamic routing, etc., have been the use cases for AI and ML models that have changed the conventional practices of scheduling and stocking goods completely.

- Cloud-native architectures provide the benefits of elasticity, scalability, and microservices.

- Security & compliance: SOC2, ISO, and EDI standards, secured comms, etc., have all worked to enhance the security & compliance aspects of the industry.

- Open APIs have opened the gateways for ecosystem integrations with WMS, 3PL, marketplaces, and billing.

- Predictive analytics have come to stay for cost modeling, ETA forecasting, and carbon tracking, among others.

Companies adopting such platforms improve SLA performance, reduce operational costs, and unlock new delivery models (urban hubs, crowdsourced workforce, green logistics). As per the estimates of McKinsey, companies that are implementing next-generation digital logistics could cut logistics costs by 20-30% and also reduce their inventory levels by 25% (McKinsey).

Why Ready-Made SaaS Is Not Always the Solution

The use of readily available Software as a Service (SaaS) Transport Management Systems (TMS) and Warehouse Management Systems (WMS) has the advantage of faster onboarding. However, in most of the cases, they do not cater to the unique workflows, multi-country compliance or domain-specific operations. Some of the instances are, regulated logistics like cash-in-transit or utilities that need secure navigation, encrypted GPS tracking, workforce dispatching, and audit trails — features that are seldom part of the standard tools.

Custom platforms became a differentiator, not a luxury, especially in logistics where optimization translates directly into margins.

Modernization Roadmap: How Companies Migrate from Legacy

Business Impact: What Companies Gain from Smart Logistics Platforms

- SLA improvements & reduced downtime

- Faster dispatching & scheduling decisions

- Lower operational costs & fewer manual tasks

- Higher customer satisfaction through ETA accuracy

- Transparent supply chain reporting

- Compliance and security upgrades

- Scalability for new verticals and geographies

This transition is not only about replacing software; it’s about aligning logistics with the speed and unpredictability of modern commerce.

Conclusion

By the end of 2025, modernization strategies shift from defensive (“replace outdated systems”) to offensive (“gain capabilities competitors lack”). Smart logistics platforms enable real-time operations, intelligence layers, and scalability — capabilities leg