1 Delivery challenges before PandaBox automation

Doner King relied on a manual dispatch and delivery management process that was expensive, time-consuming, and hard to scale. The goal was clear: replace manual work with delivery automation where efficiency gains justify the build cost.

Main pain points

- Orders were assigned manually by dispatchers — delays and uneven courier workload.

- Delivery statuses were inconsistent across channels and shifts.

- No reliable geo-tracking and mileage history per courier and shift.

- Shift performance was hard to measure (time, distance, drops, delays).

- Reporting took time and was built from scattered sources.

2 What we built with PandaBox

We built a unified last-mile delivery automation platform covering dispatch, courier workflows, real-time tracking, analytics, and system integrations.

Dispatcher & Admin Panel

Centralized control over delivery operations and decision-making.

- Real-time order and courier monitoring

- Manual overrides and exception handling

- Shift, workload, and courier management

Courier Mobile App

Structured task flow and navigation for field couriers.

- Smart route guidance and sequencing

- Live delivery statuses and proof-of-delivery

- Continuous location tracking

Analytics & Reporting

Operational visibility into speed, quality, and delivery costs.

- Delivery time and SLA tracking

- Courier productivity and performance metrics

- Bottleneck and delay analysis

Integrations & Data Sync

Reliable data exchange across internal and external systems.

- POS, ERP, and CRM integrations

- API-based data synchronization

- Scalable and extensible architecture

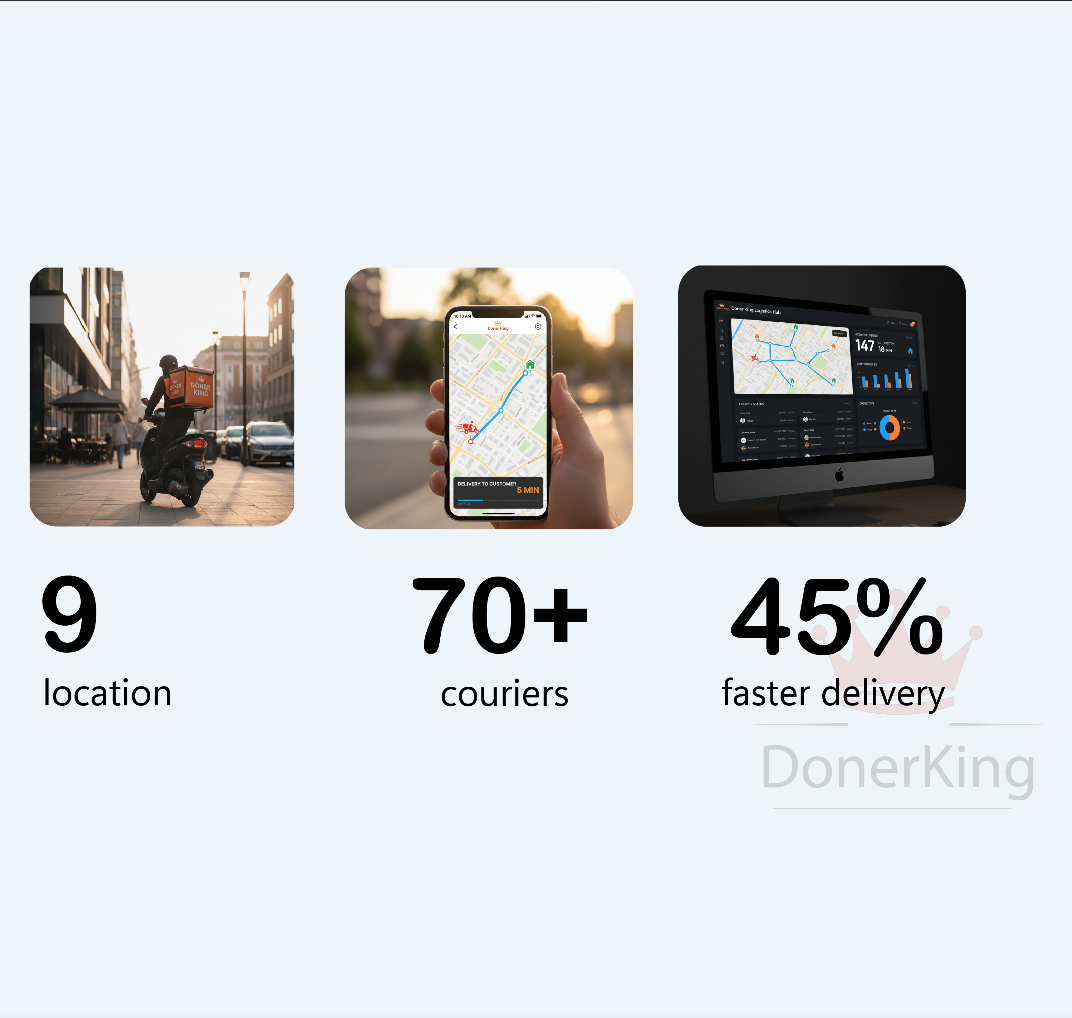

3 Results

Key outcome

45%

faster delivery time

More accurate ETAs reduced waiting time and improved customer satisfaction.

More accurate delivery ETAs

Reliable ETAs reduced waiting time and improved the customer experience.

Real-time courier tracking

Dispatchers see courier location live — fewer misunderstandings and faster decisions.

Live order statuses for customers

Customers are informed proactively, reducing dissatisfaction and support load.

Fewer dispatching errors

Clear tracking and statuses simplified delivery operations and reduced mistakes.

Bottlenecks identified and removed

Analytics highlighted weak points in the flow so the team fixed issues quickly.

Lower operating costs and simpler reporting

Performance monitoring became structured, faster, and cheaper to run.

4 Proof & next step

Today’s reality

Last-mile delivery is the deciding factor (even when food is great)

Customers don’t compare you to “average delivery” — they compare you to the best experience in the city. Predictability wins.

- Speed + reliability drive repeat orders and fewer refunds

- Proactive updates prevent dissatisfaction before it happens

- Analytics reveals bottlenecks that silently inflate last-mile cost

“

Delivery time dropped significantly thanks to more accurate ETAs. Real-time courier tracking and order statuses reduced errors. Reporting helped us identify bottlenecks and cut operating costs.

Doner King operations team

9 outlets · 70+ couriers